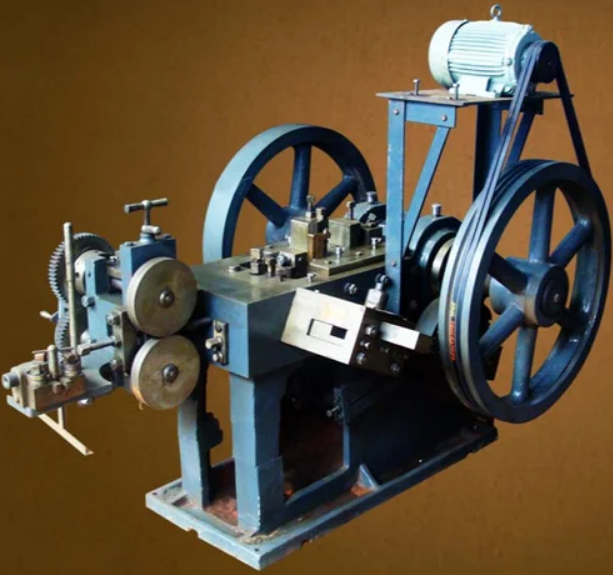

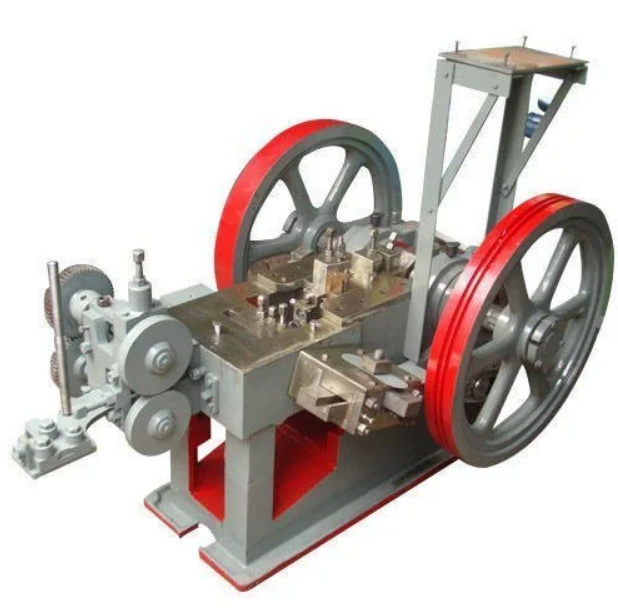

Cold-Forge Header Machine

The cold forge hex bolt header machine is a cutting-edge piece of equipment used in the manufacturing industry for producing high-quality hex bolts. This advanced machine is specifically designed to efficiently and accurately forge hexagonal bolts with excellent dimensional precision.

The primary function of the cold forge hex bolt header machine is to transform a raw material, usually steel wire or rod, into hex bolts through a process known as cold forging. Cold forging involves shaping and forming metal at room temperature, resulting in stronger and more durable bolts compared to traditional hot forging methods.

The machine consists of several essential components, including a feed system that supplies the raw material, a cutting mechanism to trim the wire or rod to the desired length, and a forming station where the cold forging process takes place. The forming station typically consists of a series of dies and punches that shape the metal into the hexagonal bolt configuration.

One of the key advantages of the cold forge hex bolt header machine is its high production efficiency. It can rapidly produce a large number of bolts in a short period, making it ideal for industries that require mass production of hex bolts. Additionally, the machine ensures consistent quality and dimensional accuracy, resulting in bolts that meet or exceed industry standards.

Furthermore, the cold forging process used by this machine improves the mechanical properties of the hex bolts. It increases their strength, toughness, and resistance to fatigue, making them suitable for demanding applications that require reliable and durable fasteners.

In summary, the cold forge hex bolt header machine is a state-of-the-art equipment that revolutionizes the production of hex bolts. Its ability to cold forge bolts with exceptional dimensional precision, high production efficiency, and improved mechanical properties makes it an invaluable tool for various industries, including automotive, construction, and manufacturing.